Investments for the environment

Iren Group has a responsible commitment to reduce its impacts and protect the environment, which it undertakes through the use of human and financial resources. The expenses and investments incurred in 2020 for environmental protection amount to approximately 490 million Euro, allocated as follows:

- 56% to the improvement and efficiency of the gas and electricity distribution networks, the upgrading and renewal of water networks, sewerage and water purification systems and smart metering;

- 40% to optimise sorted waste collection systems in order to pursue the waste recovery objectives defined in the local area plans;

- 3% to the efficiency of electricity and thermal energy production plants through flexibilisation interventions, installation of heat and electricity storage systems and development of production from renewable sources (photovoltaic and hydroelectric);

- 1% to implement services and products with positive environmental impacts for customers (e.g. Iren Plus and IrenGO).

Reduction of emissions

The Group carefully monitors atmospheric emissions (measurements on chimneys, indirect calculations, number of leaks, etc.) in order to identify specific measures to reduce them and verify the results achieved on a regular basis.

The generation of electricity from renewable sources creates significant positive effects on the reduction of emissions and the predominant cogeneration framework (production of electricity and thermal energy that feeds the district heating networks in different cities) of the Group’s thermoelectric plants significantly contributes to containing specific greenhouse gas emissions.

More than 2.7 million tons of CO2 avoided by eco-friendly energy production, sorted waste collection, material recovery and numerous other initiatives.

All power plants use renewable energy sources, waste or natural gas, for their power supply and adopt low-emission and pollutant-reducing combustion technologies (catalysts to reduce CO and NOX). Continuous emission monitoring systems make it possible to detect in real time the main pollutants and the improvement of the efficiency of the combustion process of cogeneration plants, larger thermal plants and waste-to-energy plants. The latter are also required, pursuant to the relevant Integrated Environmental Authorisations (IEA), to comply with stricter emission limits than those contained in national legislation.

Pursuant to the IPPC environmental legislation and relevant IEAs, it is mandatory for power plants with a capacity exceeding 50 MW to continually improve environmental services, by updating to the best available technology in order to continually reduce the pollution for the different environmental compartments, including atmospheric emissions.

The combustion of the biogas produced in landfills produces the maximum reduction of methane and other greenhouse gas emissions, although its conversion into CO2 has a potential greenhouse effect 21 times lower than natural gas (Source: UNI ISO 14064).

In addition to monitoring and limiting emissions from its power plants, Iren Group is increasingly contributing to reducing CO2 emissions through specific investments and projects, such as:

- district heating that uses heat produced in cogeneration, replacing traditional condominium boilers and reducing the natural gas consumption;

- heat storage systems that absorb the production capacity of plants during periods of low demand and reuse it to efficiently manage peak demand;

- sorted waste collection, which avoids the emissions that materials would have produced if sent for disposal;

- material recovery from waste, which has a positive impact on the environment, for example, through the reuse of plastics and the production of compost and biomethane from organic waste;

- sustainable mobility and reduction of employee travel through smart working and agile ways of working;

- the offer of products and services for energy efficiency and the reduction of environmental impacts by customers.

The emissions avoided by adopting the listed initiatives are summarized in the graph below:

CO2 emissions evoided (t)

(1) The calculation considers as a benchmark the emissions of the national thermoelectric system equal to 457.059 kg CO2/MWh in 2020, 479.01 kg CO2/MWh in 2019 and 478.224 kg CO2/MWh in 2018 (Terna and PNA data). Avoided emissions decreased due to the reduction in the emission factor, reflecting the gradual improvement in the national production mix. The data also includes emission reductions from heat storage systems.

(2) The calculation considers emission reductions from hydroelectric and photovoltaic plants, compared with the conventional thermoelectric mix.

(3) CO2 avoided from waste takes into account: - production from biogenic sources: landfills and biodigester with the production of electricity from biogas, electricity and heat produced by WTE, assuming 51% of the total output of WTE as a renewable source (Source: GSE) and, in case there is also the production of thermal energy, converting thermal energy into electricity (for PAI=1/6.88, for TRM=1/4.5) and applying the national benchmark (see footnote 1); - sorted waste collection: the calculation is based on the correlation between the most relevant tons of recycled waste (paper and cardboard, plastic, organic and green, wood, iron, glass) and the tons of CO2 equivalent saved (Source: Waste management options and climate change EC-AEA 2001); - material recovery: the emissions avoided by the primary materials recovered in Group plants that have been diverted from incineration (plastic, durable goods, other materials) or by the secondary raw material produced by their recovery (compost, bluair).

(4) The calculation takes into account the amount of biogas from the treatment plants from which electricity was produced.

(5) Specific projects include both internal Group initiatives (e.g. energy efficiency of plants/processes, electric mobility) and external ones (energy efficiency services, innovative Iren Plus products, sale of certified green electricity, not calculated in previous years).

| Emissions of NOX and SOX avoided (1) (t) | 2020 | 2019 | 2018 |

| Nitrogen oxides (NOX) | 467 | 690 | 812 |

| Sulphur oxides (SOX) | 271 | 435 | 489 |

(1) The calculation considers emissions that, for the same amount of energy produced, would have been generated by domestic heating systems and the national electricity production network, subtracting the emissions effectively produced by the Group’s plants.

Initiatives to mitigate environmental impacts

The Group has undertaken many initiatives to reduce the environmental impact of its activities in the various business sectors.

Environmental services

All the Group’s waste-to-energy plants are equipped with monitoring systems that guarantee continuous measurement of emissions and verification of compliance with the regulations and the Integrated Environmental Authorisation with control of the substances indicated. In order to make even more timely adjustments to the combustion parameters and to optimise the reduction of mercury, in 2020, the activities that equipped the three plant lines with a backup system for dosing activated carbon were completed on the Turin waste-to-energy plant.

In regard to the containment of the biogas emissions from landfills, cycles of internal control are carried out for the regulation of the valves at the top of the biogas collector wells with measurement of the capturing efficiency of the plant.

Another initiative regarded the replacement of diesel-powered roll on/roll off compactors with electronic equivalents. In 2020, 7 new devices were purchased, which contribute to the reduction of atmospheric and acoustic emissions.

Integrated water service

The initiatives aimed at reducing the environmental impacts mainly concern:

the reduction of energy consumption by adapting wastewater treatment processes and replacing old machinery with the latest generation equipment that consumes less energy;

- the replacement of submersed electric pumps of the pumping stations with new pumps fitted with inverters;

- the reduction of water procurement through the reduction of leaks from water mains;

- the improvement of the quality of the water that leaves the treatment plants and the connection of stretches of untreated sewage to final treatment systems;

- the abatement and containment of odorous emissions from treatment plants by confining them to secure rooms during the process in order to allow the air to be aspirated and treated.

The public water dispensers for the free distribution of drinking water (chilled and sparkling) to residents has considerably reduced the use of plastic bottles (approximately 17 million 1.5 litre bottles in 2020) and, therefore, the production of waste (588 t of PET avoided). Savings of 1,530 tons of CO2 are estimated for 2020, thanks to the non-consumption of 1,116 tons of oil equivalent for the production of the bottles.

Public water dispensers have allowed approximately 1,530 tons of CO2 to be avoided, equal to 1,116 TOE.

Gas distribution

The main environmental impact from the gas distribution network is the leakage of methane gas into the atmosphere. To guarantee the safety, quality and continuity of service levels, the Group has adopted distribution monitoring systems (for example, remote control) and intrusion detection systems, as well as ongoing scheduled research and ordinary and extraordinary maintenance of networks and substations.

Other initiatives

LED lighting: this involves the installation of new public street lighting fixtures and traffic lights with LED technology. In 2020, the initiative led to savings of approximately 17,300 tons of CO2 (see page 89 of the “Sustainability Report”).

Mobility Management

The Group is committed to reducing atmospheric emissions from road traffic through the progressive electrification of its fleet, the systematic renewal of vehicles and the promotion of initiatives for employees.

Owned and leased company vehicles as of 31/12/2020 (no.)

Atmospheric emissions of company vehicles (t)

| Types of emissions (t) (1) | 2020 | 2019 | 2018 |

| NOX | 54.56 | 91.81 | 45.01 |

| VOC | 3.38 | 4.72 | 1.78 |

| CO | 24.67 | 33.34 | 13.95 |

| PM10 | 3.93 | 5.13 | 2.58 |

| CO2 | 18,456.33 | 20,516.89 | 11,204.85 |

(1) The emissions are calculated multiplying the km travelled by the vehicles (broken down into different Euro categories, type of fuel and vehicle) by the more recent emission coefficients (Source: INEMAR - ARPA Lombardia 2018). Travel distance data were taken from the management software in use. The distances are measured using the final data of the files of the companies supplying the fuel with relevant controls on evident anomalies.

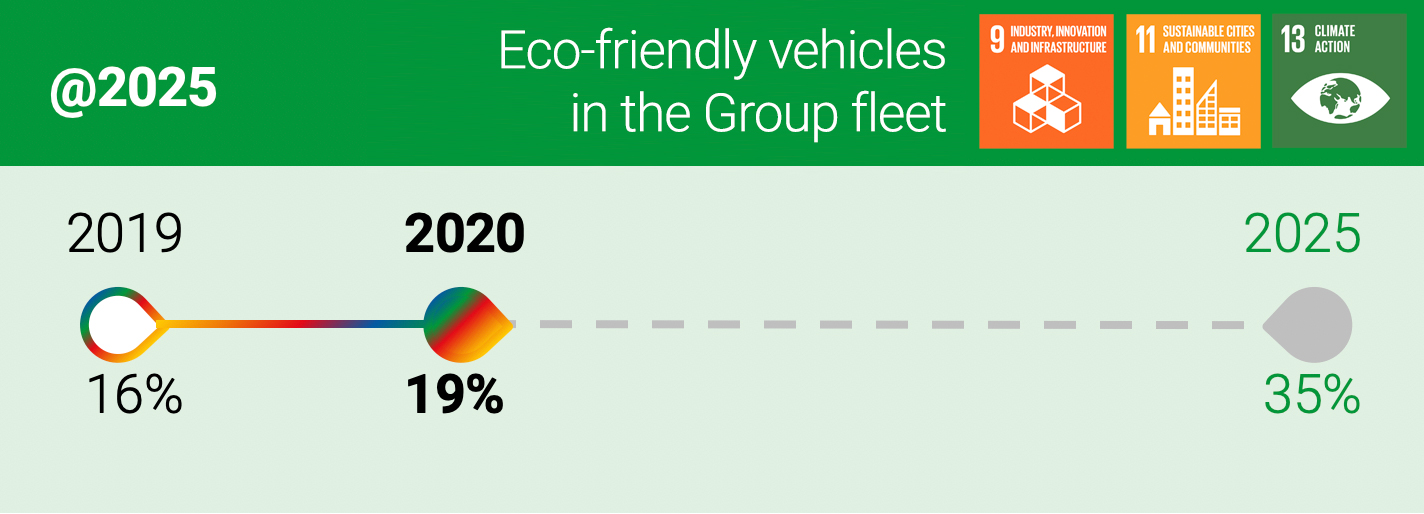

In 2020, there was a significant decrease in atmospheric emissions from company vehicles, particularly a 10% reduction in CO2 emissions, despite the growth in the number of vehicles in the company fleet. The positive trend is, in part, due to lower distances travelled related to the reduction in employee travel, but also, and above all, to the progressive efficiency and improvement of the car fleet: in 2020, the percentage of environmentally friendly vehicles in the total company fleet has further increased, exceeding 19% (16% in 2019) and the campaign to replace obsolete vehicles has continued (at the end of 2020, 62% of diesel and gasoline vehicles belong to Euro 5 and 6 categories, +12% compared to 2019).

The management of vehicles is performed pursuant to the corporate guidelines that define levels of safety, maximum distances travelled and levels of replacement in relation to total distances travelled, the age of the vehicle and level of wear and tear, together with the changing operating needs or the management synergies between the different areas of operation.

The Business Plan to 2025 confirms, once again, the initiative towards sustainable mobility: the objective is to reach 35% of environmentally friendly vehicles in the total company fleet by 2025 and 50% in the long term by 2035.

This will be possible by continuing the IrenGo project, which involves purchasing full-electric vehicles – cars, vans, vehicles for sorted waste collection and heavy vehicles – and the installation of recharging infrastructures (recharging units and wall boxes) at the company’s premises. At the end of 2020, more than 720 vehicles were already on the road (cars, vans and waste collection quadricycles) and there were more than 700 operational recharging points.

The new vehicles help to improve the air quality in the urban environments in which they work every day. In 2020, the IrenGo project avoided around 1,100 tons of CO2 and over 260 TOE.

The Group also promotes initiatives to encourage employees to use public transport (purchase of season tickets at a discounted price, in instalments or charged to their salary) and alternative methods of transportation to get to work, such as the “Ecoviaggio Smart” app, which offers employees the possibility of organising car-sharing journeys for work.

Working from home in 2020 had a positive environmental impact: 2,000 tons of CO2 avoided and nearly 1,000 TOE saved.

Also, the Group has been activating remote working methods (teleworking and “smart-working”) for several years now, which, in 2020, due to the Covid-19 emergency, were significantly extended, involving 3,166 employees. This has generated a significant positive environmental impact: in fact, thanks to the reduction in travel estimated at almost 14 million km, more than 2,000 tons of CO2 have been avoided, and nearly 1,000 TOE have been saved.